Top Notch Digitizing for Embroidery: Professional Craftsmanship

Mastering the Embroidery Digitizing Refine: Your Ultimate Guide

Needlework digitizing is a meticulous craft that requires precision and know-how to convert intricate designs right into electronic layouts for equipment needlework. As craftsmens begin on this trip to understand the needlework digitizing procedure, a thorough understanding of the essentials establishes the foundation for excellence.

Recognizing Embroidery Digitizing Basics

Embroidery digitizing fundamentals create the foundation upon which elaborate styles are converted right into machine-readable formats for accurate stitching. This preliminary step in the embroidery digitizing process is critical for ensuring that the last stitched item is a devoted representation of the original design. Understanding needlework digitizing essentials entails realizing vital principles such as stitch types, stitch direction, thickness, padding, and draw settlement.

Stitch types play a vital role in identifying the visual and textural outcome of the embroidered design. By selecting the ideal stitch kind, whether it be satin, fill, or running stitch, digitizers can achieve the desired effect and boost the general high quality of the embroidery. Additionally, sew instructions influences the circulation and measurement of the design, while density establishes the spacing and protection of the stitches.

In addition, padding sewing supplies stability to the design by safeguarding the material and avoiding distortion throughout the embroidery process. Pull settlement is another essential consideration to neutralize the all-natural tendency of fabric to agreement when stitched. Understanding these needlework digitizing basics is essential for developing professional-quality embroidered items.

Picking the Right Digitizing Software Application

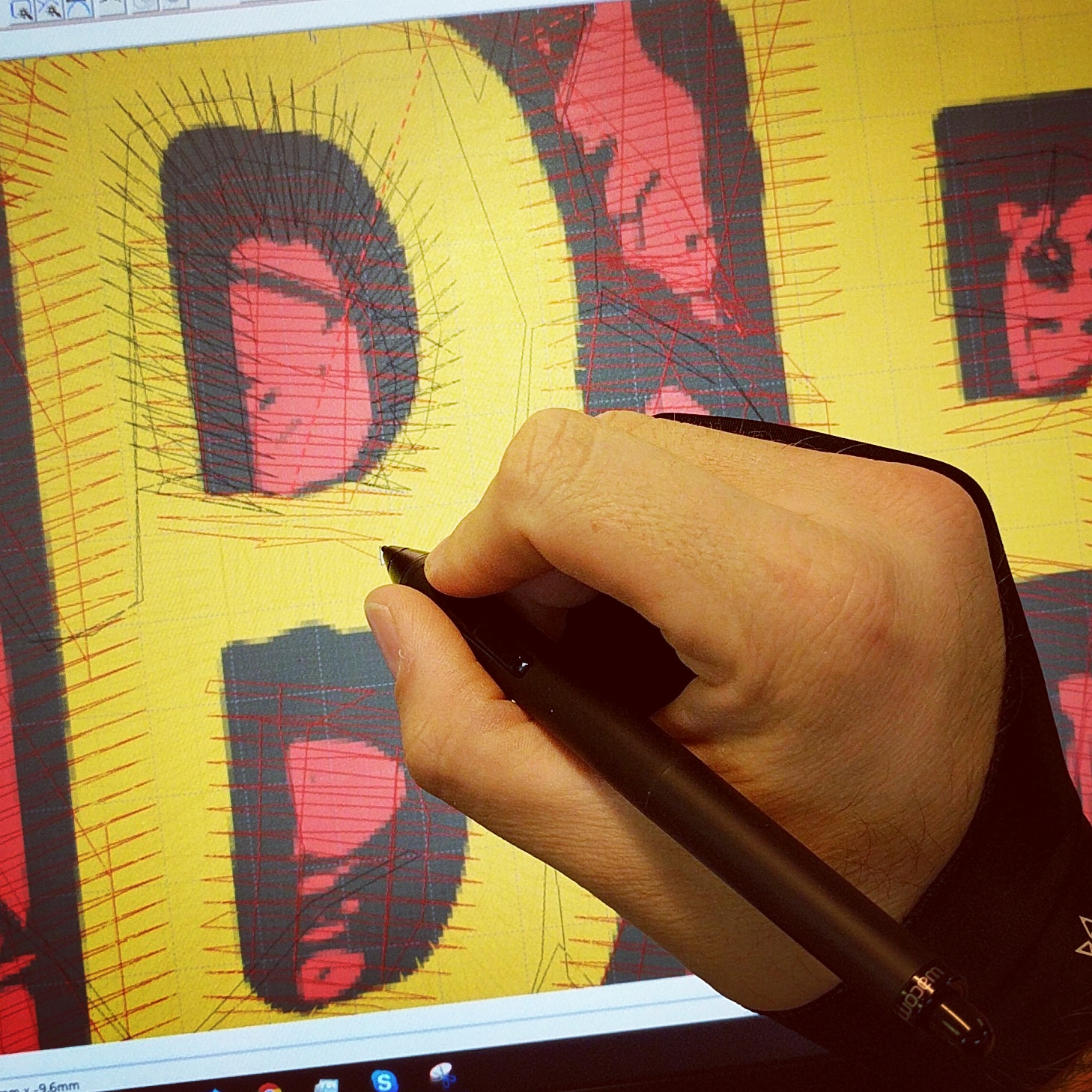

Choosing the ideal digitizing software is an essential decision that dramatically influences the efficiency and high quality of the needlework digitizing procedure. Digitizing for Embroidery. When picking the right digitizing software application, it is necessary to consider elements such as the intricacy of styles you intend to develop, the user-friendliness of the software program, the degree of consumer assistance offered, and the compatibility with your embroidery machine

There are various digitizing software options available out there, ranging from fundamental programs for novices to sophisticated software application for expert digitizers. Some prominent options include Wilcom EmbroideryStudio, Hatch Embroidery Software, and PulseID. These software packages provide a broad range of tools and features to aid you develop detailed layouts effortlessly.

Prior to making a decision, it is a good idea to check out the different software alternatives via complimentary trials or demos to identify which one best suits your demands. Furthermore, checking out evaluations and seeking referrals from seasoned digitizers can supply important insights right into the toughness and weak points of each software (Digitizing for Embroidery). By very carefully reviewing your needs and contrasting the features of different digitizing software application, you can make an educated option that enhances your embroidery digitizing workflow

Digitizing Devices and Strategies

Optimizing Layout Setup for Needlework

Grasping the intricacies of style setups is fundamental in attaining optimal results in the needlework digitizing process, structure useful reference upon the structure laid by understanding digitizing devices and strategies. When optimizing layout check this setups for embroidery, it is crucial to consider variables such as stitch type, density, padding, draw payment, and enrollment. Registration settings straighten various elements of the style properly, maintaining general style honesty.

Troubleshooting Common Digitizing Issues

When encountering usual digitizing issues throughout the embroidery process, it is essential to comprehend the origin causes and apply effective remedies quickly. One usual problem is stitch thickness concerns, where stitches may be as well thick, causing the material to tighten, or too sporadic, bring about gaps in the style. Readjusting the stitch thickness settings in the digitizing software can assist resolve this issue.

An additional constant obstacle is string breaks throughout the needlework process. This can happen as a result of different factors such as inaccurate tension setups, boring needles, or using low-quality thread. Making certain appropriate maintenance of Check Out Your URL the needlework equipment, consisting of normal needle modifications and tension modifications, can decrease the incident of string breaks.

Furthermore, style registration errors can result in misaligned elements within the embroidery layout. Examining the layout placement in the digitizing software and making necessary modifications prior to sewing can assist in preventing this problem. By addressing these common digitizing concerns quickly and efficiently, you can ensure a smoother embroidery procedure and top quality finished products.

Verdict

To conclude, understanding the embroidery digitizing process calls for a strong understanding of the fundamentals, the best choice of software program, and understanding of tools and techniques. Maximizing style settings and troubleshooting usual digitizing concerns are vital action in guaranteeing top quality needlework results. By following these actions faithfully, one can accomplish precision and performance in the digitizing procedure.